|

Globalization

and Competitiveness of Indian Auto Component Industry

Page 2 of 3

Inferior Technological capabilities

Historically the sector has been dependent on the OEM segment

for product design and did not develop the engineering

capability on its own. Most of the technology improvements

made by Indian manufacturers are through joint ventures or

technological collaborations. Foreign majors like Visteon and

Delphi have recognized the advantages of production base in

India and a large number of joint ventures and technology

collaborations are leading to up gradation of technology. In

the increasingly tired manufacturing structure, Tier-1 players

are at the forefront of technology transfer. If the Indian

suppliers wish to upgrade technology they will have to

increase the global Tier-1 players operating in India up from

4 to 15/20 and develop relation ships with large global tier-1

suppliers. Over time there has to be a shift of design and

development capability to Tier 11 and tier-111 suppliers.

Indian suppliers in these categories must eventuality raise

their research and design expenditure from current level of

0.5% to global level of 5%.

Non-tiered structure

The long

supply chain for OEMs is becoming increasingly tiered all

across globe. However, the present structure of multiple and

cascading taxation presents an obstacle for systems

procurement and discourages the tiering of the supply chain.

Consequently, Indian firms suffer from an inherent

disadvantage compared to global competition that has

additional income advantage of tiering. According to

A.T.Kearney survey, over 20-30% of all parts were

uneconomically sourced due to central sales tax distortions,

which have no MODVAT relief. Indeed the vat system as adopted

by many European nations will open vast opportunities for

competitive sourcing and tiering in component Industry.

Higher Cost

of Finance In

India

India has

one of the highest interest rates for Capital and working

capital. These can range from 12% to 18% and higher. Most of

the Indian companies work for financial institution. Where as

In countries like USA Europe funds are available at 1/3 the

cost. This makes big difference on the health of the company.

Though the financial institutions are flushed with funds, more

funds are available for investment in Non-performing assets.

The financial institutions should work out means to channelise

foreign funds at a lower rate of interest for Indian

companies.

High

Cost of logistics

The Cost to

transport parts within the country is high due to high cost of

fuel, and poor turn around of vehicles. The cost to export can

be around 5 to 25 % depending on the commodity. Ports in

India are inefficient and ship turn around times is

higher than international standards. A finished product takes

additional week to leave the Indian shores due to various

documentation and other port formalities. A container load may

cost 3000 US $ to

USA. It is

inefficient for individual suppliers to export small container

loads.

The

uncertainties in Logistics prevent Indian companies to supply

just in time. In order to make up for the environmental in

efficiencies ware housing has to be organized which can cost 3

to 4% depending on the countries.

High

Cost and poor Quality of Raw materials.

Raw

material like steel, polymers, castings etc are at times 20%

to 50% more expensive than other countries and the quality of

these raw materials also are not comparable to international

standards. Steel is the major raw material used for automotive

applications and the same is increasing every quarter.

Government may have to think of reducing the import duties in

order to bring in competition for local manufacturers.

At the firm level it has been found that the firms lack in areas like

product development, Human resource management, use of

information systems in all aspects of business, Strategic

management and exploration of future business trends. Many

firms were not proactive in anticipating the future and died

their natural death in the tierisation process.

THE PATH

TOWARDS COMPETITIVENESS

As India

opens up to globalization, the competition for the best

customers, suppliers, and talent is intensifying. Firms in

India are asking how it can become more competitive. In order

to improve their competitiveness there are numerous strategies

that leaders can use directly to improve the competitive

position of their organizations which may include changing

their portfolio of businesses, entering new markets, reducing

costs, accessing new resources, developing alliances, and

changing the rules of the game.

In order to

achieve sustainable competitiveness in long run the Individual

firms, the Government and the Industry associations have to

take certain measures individually and collectively.

Firm Level

Initiatives

At firm

level there are few gaps that need immediate focus. Most of

the firms do not have a long-term vision in terms of business

development. Since the Indian firms are currently not at par

with the best in class, there is a need for access to new

manufacturing and engineering technology and this can be

immediately achieved through some kind of association with the

Best in class firms. The nature of this association can be

licensing, joint venture etc. The Indian firms have shown poor

success rate in managing such relationships and there needs to

be a more constructive approach to wards nurturing such

relationships.

Speedy and

first time right approach to product development shall be most

critical success factor for Indian firms to exploit the global

opportunities. Product development is the weakest factor and

the reason for the shortcomings are that the customers are not

involved during development, poor capability assessment, and

inadequate virtual prototyping capability.

As far as

manufacturing capability is concerned there has been marked

improvement over few years however firms, which are

implementing JIT, Lean Manufacturing and other Japanese

practices, are showing radical improvement in business

results.

Supply

chain management is one area where suppliers have not been

electronically dovetailed with the firms. There is immense

unutilized skill and capacities available and they need to be

harnessed and utilized in order to reduce capital investments

and duplication of assets.

Firms do

not carry out utilization of Information technology for

decision-making process and overall business process

effectively. There is a vast potential for improvement in

business efficiency that can be derived out of appropriate use

of information technology.

The Cluster

of Indian Auto component manufactures constitute of around

eighty percent single part manufacturers and around 20% module

manufacturers. Firms, which are Tire-III supplier, should

evolve itself as Tier-II and eventually as Tier-I suppliers in

order to maintain its profitability and growth.

Industry

Association Level Initiatives

Associations are currently carrying out various activities.

Associations further need to take responsibility to achieve

the financial goals of the industry and spearhead the industry

as aggressively as the soft ware industry in India.

There is

unutilized capital equipment available in the industry and

there is no common database available. A common data base

should be provided to the member companies for all the unused

assets available and their where about so that these

capacities can be leveraged by the firms who need them

There are

several experts in every field available in this country.

Associations need to channelise their services to user firms

Associations need to develop a barometer to evaluate the

competitiveness of firms and industry. The Automotive

component industry should be bench marked with other

industries and strategies should be developed.

Associations should lobby and develop National Institute of

Global competitiveness for all the Industries. This institute

should be providing research and academic support to the

Industries.

Association

should evaluate the educational requirement for future need of

the industry and work with educational institutes to develop

curriculum suitable for future needs.

Initiative

at the Government level

The

Government is responsible to create a growth-oriented

environment for the industry. The Auto policy is the most

important medium to initiate various measures.

Few areas

where the Government and policy makes need to focus are

Reduce

import duties so that system suppliers have an option to

procure components from cheapest sources in the world and to

be achieving overall competitiveness.

Since Auto

industry is a capital-intensive industry, special interest

policies should be developed in order to bring down weighted

average cost of capital.

Clusterisation of industry improves competitiveness. Clusters

should be developed for different kind of components in order

to achieve overall cost competitiveness.

Competitiveness should be a National agenda. Periodic

competitiveness review of Industry and firms should be carried

out and incentives can be planned for performing firms.

Speedy

improvement of infrastructure to facilitate exports should be

carried out and that would include, roads, ports,

communication, warehouses etc.

All the

above-mentioned measures can be effectively implemented not

only by individual approach but also with the help of an

integrated task force approach.

Integrated Strategies-Recommendation

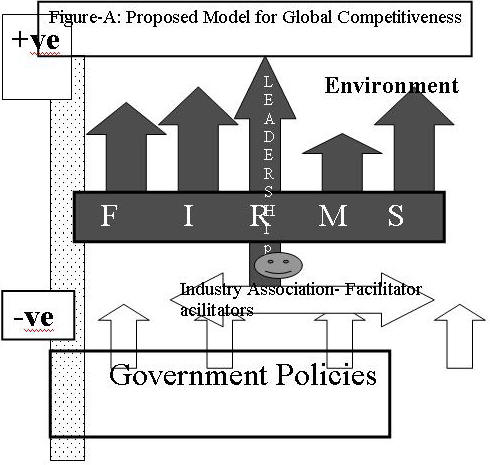

An

integrated model for competitiveness specific in context to

Indian component manufacturers is suggested by means of figure

-A

The most

important factor for competitiveness is a favorable

environment in which the firms prosper. It is the

responsibility of the government to provide appropriate inputs

to create business environment, which shall nurture firms

towards global leadership.

The role of

the associations is to facilitate the government to create a

favorable environment. In order to do so it has to carry out

continuous interaction with the firms and the government. It

has to negotiate the favorable needs for the industry with the

government.

The role of

the leaders of the firms is the most contributing factor.

Environment remaining constant there are firms that are

succeeding and some that are not. The only variable is the

leadership provided by the business professionals.

A united

effort within the framework of the model can create

environment, which can nurture growth and competitiveness for

the firms.

The model shown in Figure

A above describes the relationship between various

participants in the local environment. Individual firms

prosper depending on the quality of leadership as depicted by

arrows of various heights. These firms are working in a

business environment created by the policy inputs by the

government, and associations are the interface between the

firms and the government. In order to achieve global

competitiveness the three participants should have a common

agenda.

Seamless Global Integration:

The firms, government and associations are not

restricted to the geographical boundaries of the country and

the researcher proposes that the environment of the country

and the participants should have seamless integration with the

global economy in order to leverage knowledge and resources to

enrich the local environment.

Back

Next

|